exhibitor news

Meet us at VIV MEA 2023

Booth 09.N037

Boosting productivity at Guldfågeln with the super-efficient Physic in line thigh deboner

There’s a noticeable trend in today’s poultry market: a growing demand for high quality deboned thigh meat. But with continued supply chain volatility, delivering the right products at scale is more difficult than ever – and demands a dynamic, flexible solution.

Guldfågeln, a leading poultry processing company based in Sweden, recognized this need. Previously, the company relied on a standalone membrane thigh deboning solution that produced approximately 100 thighs per minute – and, in view of rising demand, it was clear they urgently needed a more efficient solution to maximize their capacity while saving labor.

Physic inline thigh deboner – all value, no compromise

The Meyn Sales and Innovation team connected with Guldfågeln and worked closely with them to understand their specific needs, which gave Guldfågeln the confidence to be the first customer ever to implement the Meyn® Physic inline thigh deboner! Guldfågeln needed a solution that would be simple to operate, achieving the highest throughput and least manual intervention possible – and that’s exactly what they found.

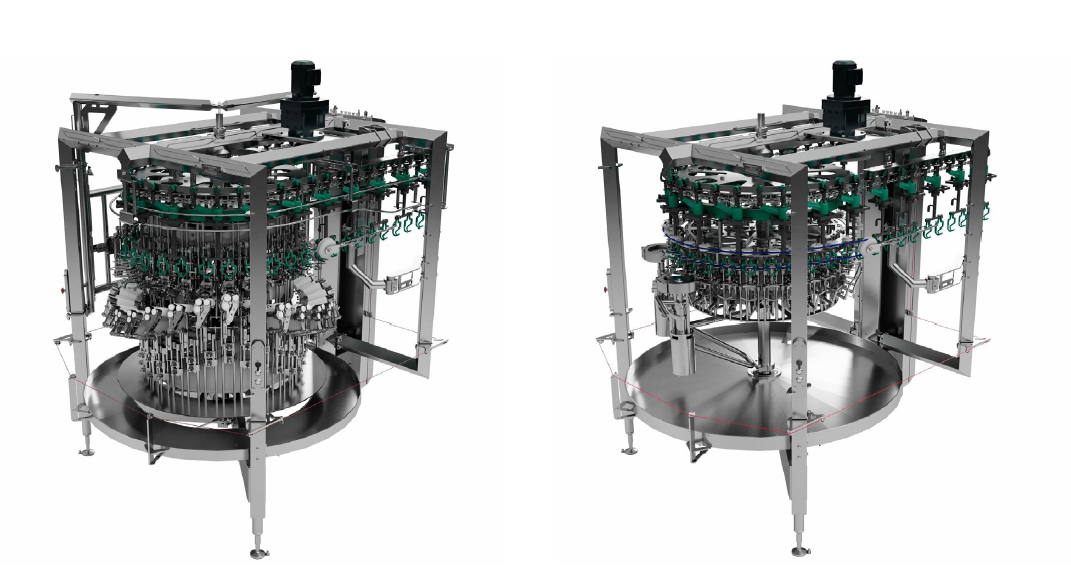

With a footprint of only 35 m2, the Physic inline thigh deboner is the most compact on the market and can be integrated easily into the cut-up line, delivering a capacity of 15,000 thigh fillets per hour processed with or without skin. It keeps the number of operators needed for inspection and trimming the lowest in the market while delivering over 92% bone- and cartilage-free fillets. There’s also no need for manual loading or rehangers, further minimizing the manpower required. Efficiency is optimized and quality is never compromised.

Exceeding expectations and beating targets

And several months later, the results are in: Guldfågeln’s pilot of the Physic inline thigh deboner delivered even more positive outcomes than expected! Firstly, it addressed their labor availability concerns by reducing the required workforce while significantly improving efficiency and throughput. Guldfågeln now operates with four fewer people per shift than initially expected – a very significant reduction. This meant a much faster return on investment (ROI) than expected, which was another positive surprise!

Alongside manpower savings, the Physic inline thigh deboner returned excellent results in terms of both yield and quality, in products with or without skin.

And the key to all this success? A great collaboration! We were very proud to hear that Guldfågeln was impressed with the professional support they received from Meyn throughout the implementation, as well as the improvements in productivity. We’re looking forward to continuing our great working relationship in future – and we’ll take forward this positive experience to bring even more value to other customers, too.

“Our goal was to increase thigh deboning capacity with the least number of employees possible without compromising our high-quality standards. We have had the machine in operation for six months and are convinced that the Physic in-line thigh deboner has exceeded our expectations in terms of throughput per man-hour, yield, and simplicity.”