exhibitor news

Meet us at VIV MEA 2023

Booth 09.M037

Connect for success

During the VIV MEA exhibition, Marel and its partners AACE and RootsAFS will focus on semi and full automation of poultry processing, as this can be the connection to successful growth for many Arabian processors.

Discover how our product portfolio seamlessly aligns with the Middle Eastern market, enabling poultry processors to advance towards tailor-made automation.

Automation in the primary process

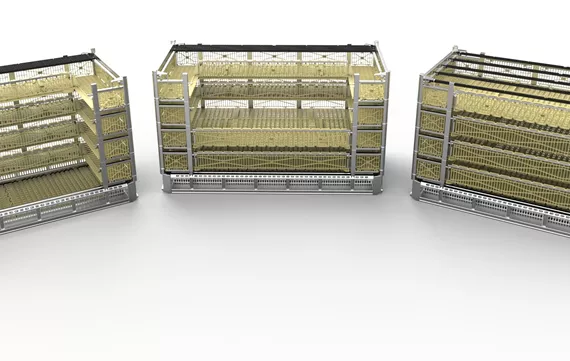

The ATLAS live bird handling system is gaining increasing attention in the Arab world due to its perfect alignment with local demands and expectations. ATLAS sets new standards in efficiency, hygiene and animal well-being. The cleverly designed SmartStack transport module prevents bird stress from farm to shackling. Featuring the largest headroom in the industry, ATLAS needs fewer transport movements, reducing CO2 emissions.

Marel’s Nuova automated eviscerators can make a real difference, as they can grow along with expanding businesses. Starting with a Nuova CoreTech will secure a future-proof evisceration concept, allowing for the addition of more units, automated viscera pack line and automated giblet processing. The Nuova concept offers many benefits in terms of hygiene, handling and harvesting.

Cut-up and deboning

In the Arab world, there is a noticeable shift toward cut-up and deboned poultry products. Previously, this market primarily focused on whole chickens. Today, some poultry processors allocate as much as 70% of their production to cut-up products, with only 30% dedicated to whole chickens. In addition, fixed-weight packing of fresh chicken pieces is becoming very popular, significantly exceeding the quality of imported meat. Marel provides Arab poultry processors with robust solutions to address thesecut-up and deboning trends.

ACM-NT is an extremely flexible modular cut-up system that can produce a wide variety of anatomically cut products according to production wishes. An ACM-NT Compact cut-up system can be configurated in many ways thanks to its flexible layout. It all depends on the kind of end products to produce. Is there a focus on wing products, leg products or breast products? Once the appropriate modules that comply with the customers’ end product demands have been chosen, ACM-NT Compact does what it needs to do and fulfils all product needs.

The AMF-i breast deboning system features adaptive intelligence. AMF-i automatically detects the size of uncalibrated breast caps fed to the system. You no longer have to select manually a product size related recipe, as module settings adjust themselves automatically to the measured product size. In this way, the intelligent AMF-i system achieves adaptive filleting with highest yield with no human intervention needed.

Focus areas

Convenience food production and Water Treatment will be two focus areas for Marel at VIV MEA.

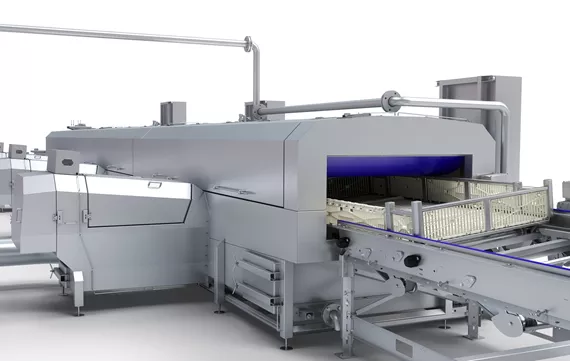

Marel’s convenience line configurations are ideally suited for businesses that are looking to develop further processed products, such as nuggets, wings, strips and burgers. Marel uses the latest technologies in further processing to help processors add value at every step in the production process. Starting with the efficient preparation or portioning of the poultry meat, then forming, coating, frying and cooking products to perfection. To finish the process, our end of line equipment can grade, batch, pack and label products ready for dispatch.

Marel’s cost-effective, sustainable and energy-efficient water treatment systems solve some of the most difficult challenges with wastewater disposal. When implementing wastewater treatment in the process, Marel’s expertise, developed over more than five decades of partnerships with our customers, is ready to configure a tailor-made process.

With innovative solutions Marel can support Arabian entrepreneurs in transforming their poultry processing operations. Connect for success!