Meet us at VIV MEA 2023

Booth 08.G040

Make money from manure with Kohshin, Japan

What is Kohshin Engineering? Kohshin Engineering is a leading innovator in composting technology. Our cutting-edge equipment has been specifically designed to assist farmers in efficiently converting large quantities of manure and bio-waste into high-quality organic fertilizer.

When we mention the word “manure,” what immediately comes to mind? Problems? Smell? But what if we told you that manure can actually mean GOLD and HEALTHY SOIL! It may sound unbelievable, but it’s true. And at Kohshin Engineering, we have developed special equipment to support your every step of the way in transforming smelly waste into safe and nutritious fertilizer.

Let’s start from the beginning. What are the benefits of composting for countries with hot and dry climates?

- Soil improvement: compost helps enhance the soil’s ability to retain water.

- Nutrient enrichment: compost is essential for nutrient-poor desert soil.

- Disease prevention: enhanced and enriched soil plays a crucial role in preventing diseases in plants. Improved soil quality serves as a defense against various plant diseases.

- Temperature regulation: acting as a natural insulator, compost protects plant roots from excessive heat stress.

Now, let’s delve into how our Kohshin Composting Equipment works.

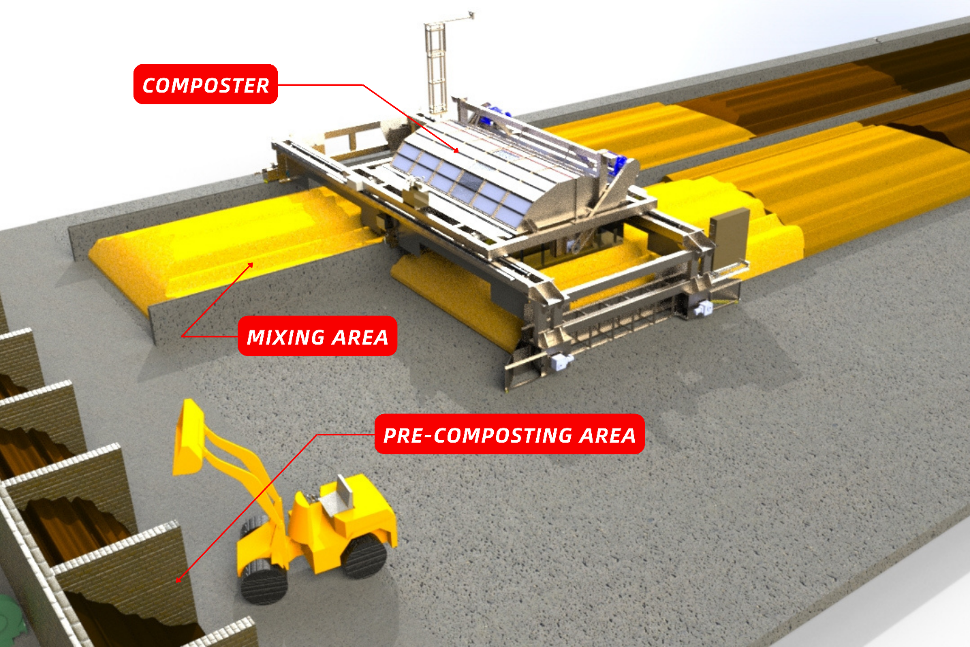

Step 1: Pre-composting

During this stage, we adjust the moisture content of the materials and ensure proper aeration. This activates aerobic bacteria, which in turn increases the temperature. This temperature increase helps kill harmful pathogens and bacteria. Additionally, the aerobic microorganisms begin breaking down complex components, thereby accelerating the entire composting process.

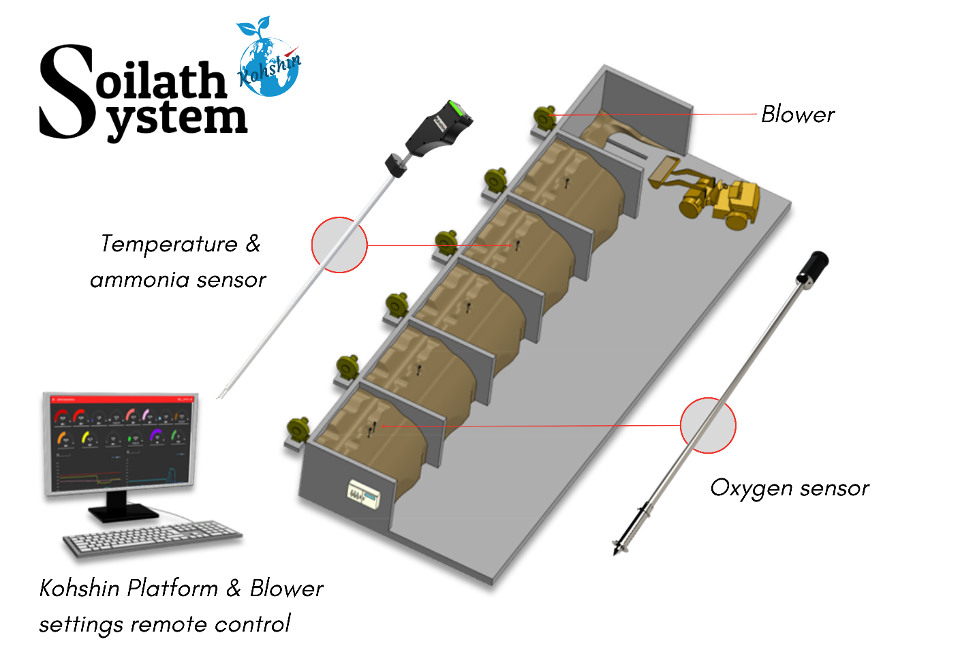

To assist our clients during this crucial stage, we have developed the pre-composting Soilath® System. This system includes four different types of sensors: temperature, ammonia, oxygen, and outside temperature/humidity and the application/platform which collects data from these sensors, analyzes it, and provides remote control over blower timer settings. This means you can adjust the timer settings or turn them on and off, even if you are thousands of kilometers away from your farm site.

Principle of Operation: Begin by placing the mixed materials into the aerated pre-composting pit. Next, insert the sensors and monitor the data received from these sensors through the Kohshin platform. Based on the information gathered, adjust the blower timer settings accordingly.

Step 2: Kohshin Composter

Once the pre-composting period, which typically lasts from 6 to 8 days, is complete, the materials are transferred to the Kohshin Composter for the agitation process. Our composters utilize an advanced aeration system to maintain the aerobic process. This ensures that the bacteria continue breaking down the components, while the high temperature effectively eliminates any harmful pathogens. There is no need to add any additional bacteria or substances.

It is crucial to note that our machines do NOT dry the manure; instead, they transform it into a complete and mature compost. When it comes into contact with water, it does not produce any smell or return to its original manure state.

Principle of Operation: To begin, place the materials on the INPUT side of the composter. Then, the machine will start agitating the materials pushing them towards the OUTPUT side on a daily basis for a month. After approximately a month, you will start receiving a fertilizer every day. At the same time, the aeration system, which is carefully set up, will consistently maintain the aerobic process, effectively eliminating harmful pathogens and generating safe and nutrient-rich fertilizer. By implementing these biological processes, we are able to produce a safe and ready-to-use compost that can be directly utilized or sold to other companies and farms, thereby creating a new source of income.

Additionally, our composters are equipped with uniquely designed hatchet blades that ensure uniform chopping of the materials. In the case of pure chicken manure, the final product is even more pelletized and granulated.